[Willoughby, OH June 24, 2024] – Lokring® Technology, LLC, a leading innovative fitting manufacturer is unveiling a revolutionary patented sensor product for its Lokring-Coldweld™ line of ASME code compliant fittings. This product, part of Lokring’s Smartlok™ product line, is known as Lokring Smartlok Diagnostic Sensor.

This product launch represents a significant step forward in industrial monitoring, combining cutting-edge IoT (Internet of Things) technology with unparalleled expertise in fitting engineering and manufacturing. Strain sensors have been used in many laboratory applications for Design of Experiment (DOE) in order to gain better perspective and data from metal specimens when external forces are applied.

After initial prototyping, Lokring enlisted Embedded Planet, to develop the final IoT sensor and software configurations. This concept shifts from a lab metal specimen to the actual fitting which measures its own strain applied during pull up of the fitting, and the permanent strain reading expectation through the life of the product.

Stress and strain result when an external force or a purposeful pull-up hydraulic force/load is applied to a metal driver which ensures a safe and leak-free cold weld connection to mating sticks of pipework. Other pipework external strains can be measured, including pipe weight, and expansion and contraction.

Innovative Monitoring for Lokring-Coldweld™ Connectors

This new product combines the strength of the Lokring-Coldweld™ technology with strain monitoring that improves performance and safety for all industrial installations. The new sensor, specifically designed for Lokring fittings, is an IoT-based device that attaches seamlessly to the product and monitors the product’s drive ring after the fitting is pulled up.

The IoT sensor monitors the joint post-installation, measuring strain and ensuring the integrity of the connection. This ongoing monitoring is crucial in maintaining safety and efficiency in high-stakes environments like industrial manufacturing facilities, power plants and oil refineries. It is also pivotal in preventing equipment failures and ensuring continuous operations in demanding industrial environments.

The Smartlok™ product is designed for lifecycle extension of pipework systems, and acts as an early warning system of piping and fitting anomalies.

State-of-the-Art Energy Harvesting Technology

In a remarkable advancement, this sensor functions without a conventional power source. It is equipped with a patented innovative photovoltaic (PV) energy-harvesting system that draws power from a solar unit that is only 1.638” x 1.035”. This unit runs on ambient light in a typical office environment or can be powered by a flashlight from 15-20’ away.

This approach eliminates the need for batteries, reducing both maintenance requirements and environmental impact. The solar panel powers the Smartlok and enables remote data acquisition from the sensors.

Wireless Data Transmission for Enhanced Convenience

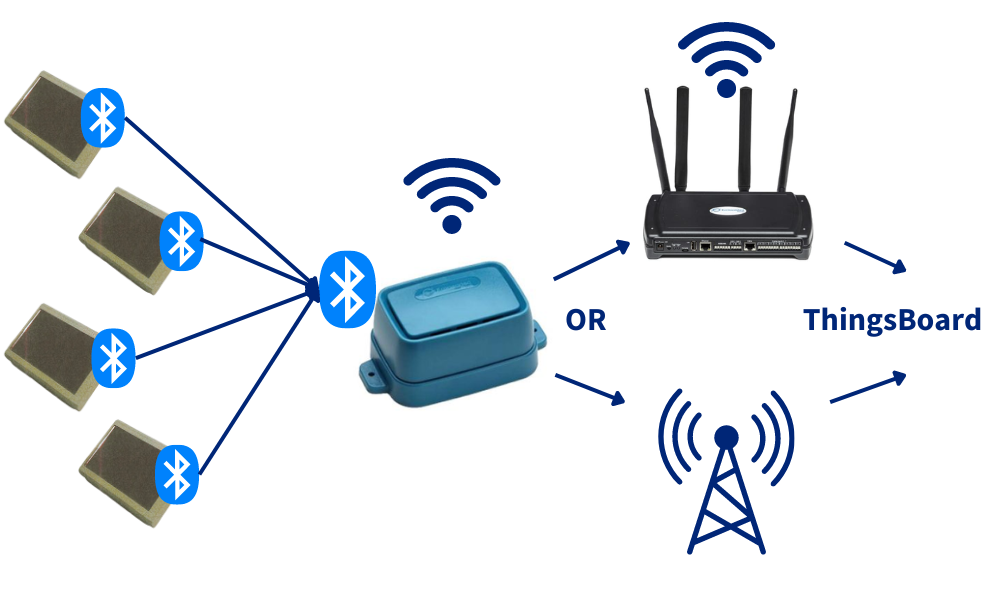

The collection unit gathers data and uploads it to the cloud via Wi-Fi or cellular to eliminate the need for human interaction. Smartlok also uses multiple sensors transmitting to a single data unit that uses Bluetooth to wirelessly transmit data to a handheld Android device that is running the Lokring app. This feature allows for daily, hassle-free readings, enabling maintenance staff to easily monitor the strain on installed fittings.

The Lokring app transmits the data using Wi-Fi to the Lokring cloud. The Lokring cloud includes a dashboard that enables strain readings to be analyzed over time. In addition, if the handheld is out of range of Wi-Fi, the data readings are timestamped, stored locally on the handheld, and transmitted asynchronously to the cloud when the handheld comes back into Wi-Fi range. This approach means that readings can be taken in places that do not have immediate access to the internet.

Redefining Industrial Monitoring Standards

Lokring Technology had already developed IoT concepts while working with Phase IV in Boulder, Colorado and was looking for a local IoT source to further enhance the data acquisition and cloud-based systems. Lokring and Embedded Planet were able to create a product that meets the stringent requirements for monitoring, transmission, durability, and data analysis.

User-Friendly Design and Seamless Integration

Tailored for ease of use, the sensor integrates effortlessly into existing systems, boasting a user-friendly interface that ensures swift adoption in diverse industrial settings. Its compatibility with standard handheld devices means that integrating this advanced technology into daily operations is both simple and efficient.

Product Release Information

The new Lokring Smartlok Diagnostic Sensor is projected for availability in Fall 2024 through Lokring’s exclusive distributors. Detailed information about the product, its applications, and the benefits it brings to industrial operations can be found on the website for Lokring Technology – www.lokring.com.

About Lokring

Using state-of-the-art technology, LOKRING® Technology designs and produces the most advanced fluid and gas transfer connectors on the market today. Manufactured in Northeast Ohio, LOKRING® fittings are produced under quality systems in compliance with ISO 9001:2015. The patented LOKRING® connector was derived from aerospace technology and is a superior quality, leak-free fitting that is extremely reliable, easy to install and requires no heat for installation.

William Lennon

Inventor of the patented Smartlok™ Diagnostic Sensor

President/CEO, Lokring Technology